There are 92 naturally occurring elements but only one, uranium, has become the element of choice as a fuel for commercial nuclear operations.

Uranium has an atomic number of 92 and corresponds to the chemical symbol U in the periodic table. It is a member of a unique class of elements known as “actinides,” which were discovered relatively late in history in 1789. Uranium is “radioactive,” meaning that it decays over time and releases energy, much like all other actinides. Because of its unique qualities, uranium is the primary fuel used in nuclear reactors; a lare pea-sized pellet of uranium fuel contains the energy of one ton of coal or about 150 gallons of oil.

Approximately 500 times more common than gold, uranium is one of the most abundant elements in the crust of the world. Small quantities of uranium are found in rock, soil, water, and even human bodies. The ocean has four billion tonnes of extremely diluted uranium.

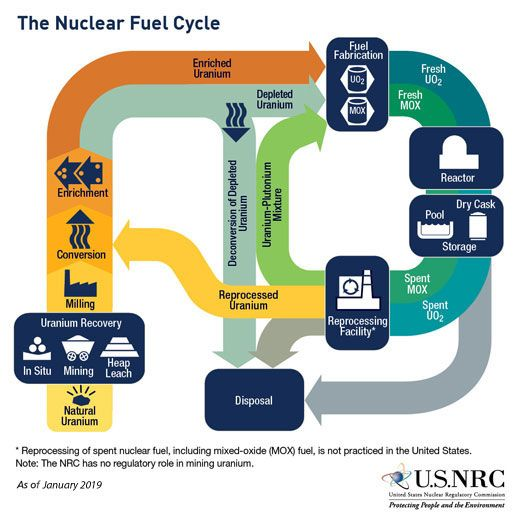

Most uranium ore was extracted from open pits or subterranean excavation sites in the 20th century; to isolate uranium from other elements, the ore needed to be crushed and processed. This technique has been progressively superseded in the twenty-first century by “in-situ leaching” which is regarded as environmentally preferable to other techniques and more cost effective. Even though in-situ leaching produced only sixteen percent of all uranium in 2000, it is the most widely used method of uranium mining today. By 2020, this form of mining accounted for around 58% of all uranium mined worldwide.

In-situ leaching leaves the ore where it is in the ground and retrieves it by dissolving it in a solution of water and reactants and then pumping the resulting solution to the surface. The uranium is then recovered by drying and filtering. The end product is a coarse powder that has a pungent odor, is insoluble in water, and contains about 80% uranium oxide (U3O8), called yellowcake. The yellowcake is then smelted into purified UO2 for use in fuel rods, after being enriched with U-235.