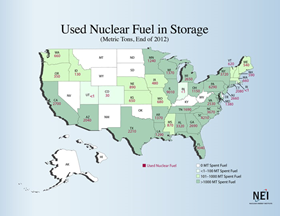

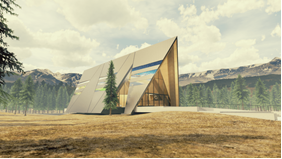

Surely, by now you have heard about Oklo Incorporated, founded in 2014, the company that has the Aurora 1.5 MW micro-reactor design. They may have a solution for disposal of the used nuclear fuel assemblies in storage across 30 of our states (~80,000 metric tons).

They have submitted an LPP (Licensing Project Plan) to the NRC (Nuclear Regulatory Commission) for a Fuel Recycling Technologies Facility. The LPP essentially outlines the company’s plans for “pre-application engagement activities that support the future licensing of a first-of-a-kind fuel recycling facility,” the company said on January 25, 2023.

The privately funded commercial-scale fuel recycling facility will produce a mixture of fissionable uranium and transuranic element isotopes, using an electrorefining-based technology to recycle the used nuclear fuel. This process differs from the legacy reprocessing method because electrorefining keeps the major and minor actinide elements combined. For this reason, many refer to the electrorefining process as inherently ‘proliferation-resistant’. Oklo also plans to use these materials to manufacture fuel for their fast micro-reactor(s).

According to Jacob DeWitte, co-founder and CEO of Oklo, launching the first-of-a-kind facility that will recycle used fuel from other reactors, as well as Oklo’s own reactors, marks an important next step for the company. “The ability to economically recycle fuel is an important attribute for developing domestic fuel supplies, and offering recycling services also presents a sizeable opportunity,” DeWitte said on Wednesday. “We are taking a major step forward in bringing meaningful fuel recycling capabilities domestically that will produce cost-competitive fuel.”

Although the NRC staff recommended the NRC discontinue Spent Nuclear Fuel reprocessing and the recommendation was approved in 2021, Oklo sent a letter to the NRC acknowledging that its submittal of an application for a fuel recycling facility “would be the first in many years, therefore requiring alignment with NRC staff on approaches to complying with existing requirements.” They believe there is a pathway to licensing a commercial fuel recycling facility through the existing NRC regulations, therefore, no need for new rulemaking. They are already engaged with the NRC staff on fuel recycling, and they intend to use the existing regulations “without delay”.

While the NRC denied their COLA (Combined Operating License Application) for the nuclear micro-reactor project planned for the INL – Oklo relaunched the licensing process for this project in September 2022.

Oklo’s track record to date, is pretty accomplished, they have won four Department of Energy (DOE) competitive awards for fuel recycling, including three awards granted in 2022. The four awards, which amount to about $17 million, “involve technology development in support of commercializing production of advanced reactor fuel from used nuclear fuel (UNF)” – also referred to as spent nuclear fuel (SNF) or nuclear waste. In 2019, Oklo also notably received a “first-of-its-kind” site-use permit to build its Aurora plant at the INL site in Idaho Falls, Idaho, and in 2020 it became the first modern advanced reactor design firm to secure access to recycled HALEU fuel from INL for demonstration purposes.